Alternator In Aircraft - When you see a discharge indication, the first step is to turn off the alternator side of the master switch. If you do not have a split master switch, we recommend turning off the radios (to protect them from a potential voltage spike), and then turn off the master switch.

An engine-driven alternator uses the principle of electromagnetic induction to generate a constant supply of electricity once the engine is running. This generated electricity is then routed to the busbar where it feeds into the electrical system and runs the various electrical components operated during flight.

Alternator In Aircraft

The alternator also charges the battery while the engine is running. A Direct Current (DC) system is used to power the electrical components on an aircraft; an alternator produces an Alternating Current (AC) and so must be converted to DC via a rectifier before entering the busbar.

Introduction And System Overview

The AC alternator and DC generator are covered in more detail in the next post in this series. The rule of thumb used to be that an owner could expect to replace the alternator twice between engine overhauls.

If it got to be more than twice, there was probably a problem with the charging system or cooling the alternator. Now we are hearing that alternators on airplanes that are flown regularly are lasting over 3000 hours.

The field wire should only be removed from the alternator with the master switch off. If the master switch is turned on with the wire removed, take precautions to prevent the field wire from touching anything that would allow it to short to ground.

The voltage regulator can be ruined if that happens. The CSD is a hydraulic unit similar to the automatic transmission in modern cars. Just as how the engine can change its rpm while the speed of the car is constant, the same process occurs in the AC alternator of an aircraft.

How Alternators Work

Even if the plane changes speed, the alternator rpm will remain constant. This process can be controlled either electronically or mechanically, but in modern planes, it is always electronic. The constant speed drive allows the alternator to produce the same frequency at just above idle as it does at maximum engine output.

Finally, a failure in flight of the alternator is identified by a discharge on the ammeter or the illumination of the generator warning light. This will lead to a situation where the electrical system will stop working once the battery fully discharges.

If this occurs in flight, and there are no blown fuses or open circuit breakers, then it is sensible to reduce the electrical load as far as possible by switching off all non-essential electronic components. It is not wise to continue a flight with a failing electrical system and so diverting to the nearest safe landing strip may be the best option.

It is worth reiterating that the aircraft ignition system is separate from the electrical system so the engine will not stop, even during a full electrical failure. Generators are more common on jet-powered airplanes. Generators can be used as starters too.

Types Of Electricity

Battery power is used to spin the generator, which spins the engine up for starting. Once the engine is running, the engine spins the generator to make electricity. Aircraft alternators and electrical systems aren't complicated once you understand how current flows through the system's various parts.

With a solid understanding of how the system works and an aircraft-specific wiring diagram in hand, combined with these tips for troubleshooting and the assistance of a friendly mechanic, a pilot/owner can diagnose many common problems.

Unlike cars, which use the alternator and battery to produce the engine's ignition spark, planes use separate magnets to do the job. In most cars, if the alternator fails the engine will die after the battery is drained.

But pilots can even turn their electrical power off in flight without risking the engine stopping. The engine requires no electrical power to run. When the charging system discharges, troubleshoot it carefully because it's a 50% chance it's not the alternator.

Electricity On Airplanes

If it is the alternator and you can afford the time, we think that you can save money by sending it out for inspection and, potentially, repair. If replacement is required, we lean towards Plane Power units.

If the voltage regulator is not receiving power from the bus, the next upstream component is usually an overvoltage sensor. Again, always consult the wiring diagram—some airplanes don’t have overvoltage sensors at all, and some overvoltage sensors are incorporated into the voltage regulator itself.

We were told that when alternator replacement is needed, most owners go with the type of alternator in the airplane. We have no quarrel with that approach, although doing a little shopping might result in finding another model at a lower price.

That means pulling the charging system schematic for the airplane as well as accessing a good set of troubleshooting guidelines for the charging system. With absolutely no humility at all, we recommend the ones set out in the January 2016 issue of Aviation Consumer.

Circuit Breakers

Most airplane electrical systems are "single-wire," meaning that the airframe itself is used as a ground, eliminating the need to run two wires for a positive and ground connection to each electrical component. They are also DC systems, meaning that the components operate on direct current rather than alternating current (AC).

As we go to press we note that respected alternator manufacturer National AirParts closed its doors last April. The phone is not being answered, so we were not able to determine if National approved any shop(s) to repair or overhaul its line of alternators.

If you have a National alternator, it may be an orphan. We'll keep you advised if we hear news that any shops are approved to repair and/or overhaul those units. We'll take a moment and talk about what to do with a failed generator.

The unanimous recommendation from maintenance techs and users was to upgrade to an alternator via an STC'd kit. We saw prices for the kits starting at $495, including a new, 12-volt alternator, from Quality Aircraft Accessories (www.qaa.com).

Alternator Is Not Charging; Rotor Is Not Magnetized

Prices go up as the alternator output increases. The pulleys over which the belt runs need to be checked for alignment as misalignment can lead to accelerated belt wear and failure or to the belt coming off of the pulleys.

The belt should be soft, flexible and free of nicks, cuts and significant wear. The alternator's rotor gets its electrical connection through two carbon brushes that ride on separate slip rings. One of the brushes transmits positive current from the voltage regulator to the rotor windings and the other provides the ground connection, either from the F2 terminal or from an internal ground to the alternator frame.

If the rotor is magnetized and appears to be working properly, the next step is to see if there is bus (battery) voltage on the B+ terminal of the alternator. If there is bus voltage there, it means that the circuit between the alternator output and the bus bar is intact.

The electrical system installed on an aircraft comprises of two electrical sources: a battery which is primarily used to operate the system when the engine is not running, and an alternator (or DC generator), which runs off the engine and is designed to provide a

Charging

continuous supply of electricity to power the various electrical components and charge the battery once the engine has started. It is essential that the aircraft be self-sufficient with respect to its electrical requirements, as a battery has a finite capacity and will discharge as it is used.

A generator or alternator installed on the aircraft can both supply the electrical components and charge the battery – ensuring that there is always sufficient battery capacity to start the engine on the next flight. The rotor is an electromagnet whose magnetic strength is controlled by the amount of current it receives from the voltage regulator.

This allows the voltage output of the alternator to be regulated. If the rotor were made with a permanent fixed-strength magnet, voltage output would be unregulated and would vary with engine rpm. The battery is connected to a master switch which when turned on will feed battery power directly to the busbar, powering any electrical components that are turned on.

For example, turning on the master switch and rotating beacon light will route electrical energy from the battery to the beacon via the busbar. As to favored alternator manufacturers, we were told that after Kelly alternators were taken over by Hartzell Aerospace, their quality improved.

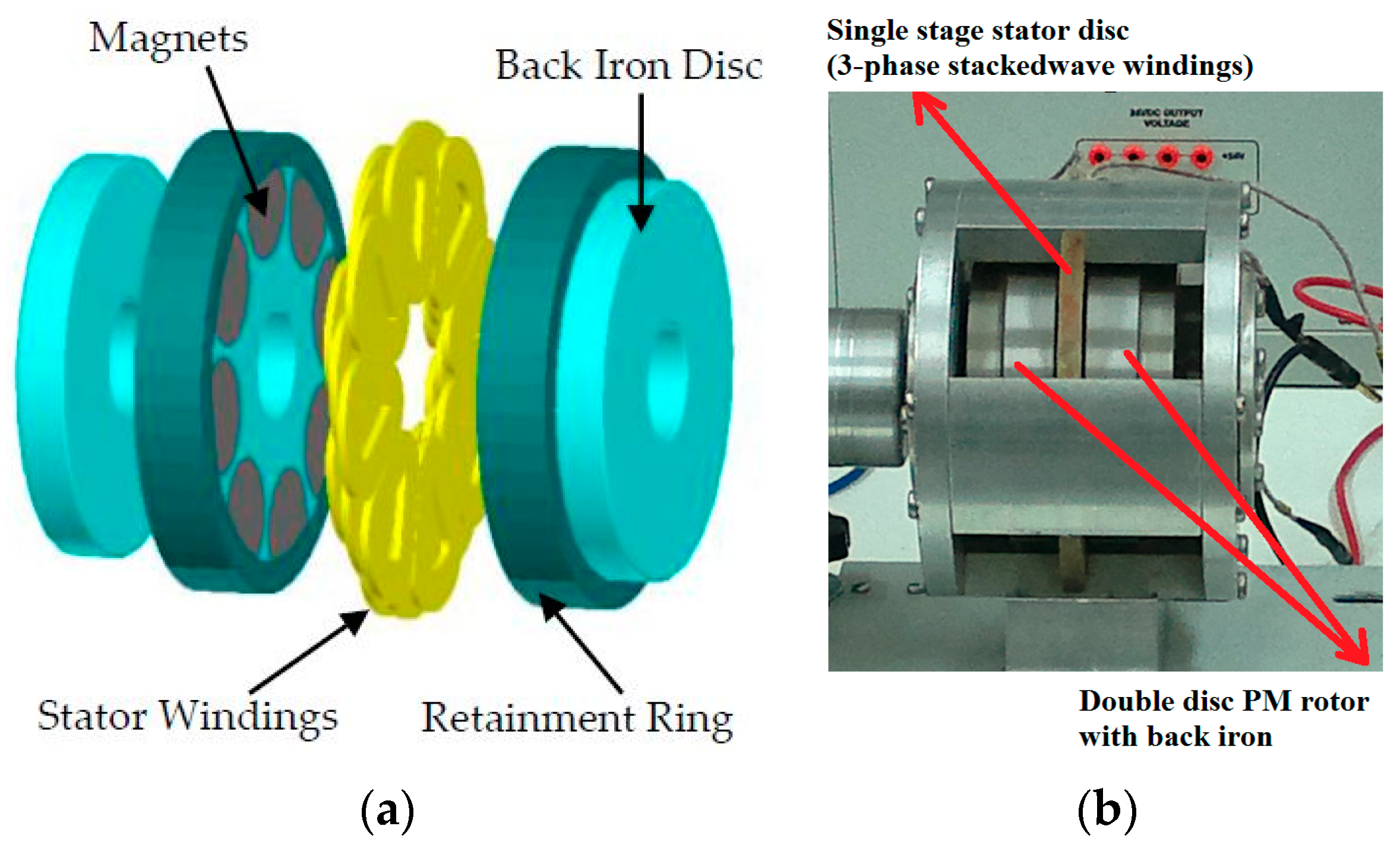

Aircraft Alternator Design

We also heard nothing but praise for Plane Power alternators from users and techs. For the first time since we've looked at the subject of alternators, we received no bad reviews for any type. Alternators generate electric current based on the principle of magnetic induction.

Any time magnetic lines of force have relative motion with a conductor that is in close proximity, a voltage will be induced in the conductor. Having even a little bit of power helps. Most small aircraft have an alternator, just like cars do.

The alternator charges a battery, which is used to store energy to help start the airplane and run equipment if the alternator fails. The power generated on an aircraft is used to charge a battery and run small electronics.

As such, it is much more like the power generated by your car than what comes out of the outlets in your home. Jacqueline Shipe grew up in an aviation home; her dad was a flight instructor.

In Flight

She soloed at age 16 and went on to get her CFII and ATP certificate. Shipe also attended Kentucky Tech and obtained an airframe and powerplant license. She has worked as a mechanic for the airlines and on a variety of General Aviation planes.

She's also logged over 5,000 hours of flight instruction time. Send questions or comments to . We asked maintenance techs about the reliability of new versus overhauled alternators and got the disconcerting answer: “It’s a crapshoot.”

We heard horror stories about early failures of both new and overhauled units-although they were replaced under warranty-along with praise for long-lived overhauled and new units. An alternative to the ammeter is a device called a loadmeter.

This dial has a scale starting at zero and shows the output of the alternator. During normal operation the loadmeter will show the sum of the load required to run the active electrical components and the load required to charge the battery.

Alternator Is Not Charging

Bus voltage should be checked before starting the engine, and then checked again with the engine running to compare battery voltage (not running) to alternator output voltage (running). If the two voltages are identical, the alternator is not charging at all.

If the regulator is receiving power from the bus, check next for a good ground connection for the regulator. Some regulators have a ground wire that is connected under one of the mounting fasteners, and some regulators require a good ground connection between the regulator body and the airframe ground.

These connections can corrode over time, causing too much resistance in the ground connection. Cleaning the connections with Scotch-Brite or a small piece of sandpaper usually re-establishes a good ground connection. But they are big enough to make electricity to use in the plane and recharge those batteries.

They also make bleed air, just like the main engines, which can help start the main engines. They also use their bleed air for environmental systems. Circuit breakers are labeled with the current draw that will cause the breaker to pop.

Alternator Drive And Control Systems

It is important to install a breaker with the correct current rating to properly protect the sensitive electronic equipment. Using a breaker with a limit higher than specified for a particular piece of equipment will not protect it in the event of a current surge.

Conversely, a breaker with a lower limit than specified for that equipment may result in unnecessary trips during normal operation. For more than five decades, active and dedicated aircraft owners and pilots have turned to AVIATION CONSUMER to answer their most important buying questions.

This website contains many older reviews. Unless otherwise noted, these reviews carry product pricing from the time of the original review. If the alternator is charging, the voltage should be noted and then all the electrical equipment on the airplane should be placed in the on position.

With the lights, radios, pitot heat and other electrical components turned on, the alternator should carry the full electrical load and still maintain a positive charging rate.

Circuit Breakers And Fuses

aircraft alternator overhaul, plane power alternator repair, aircraft alternators for sale, aircraft alternator how it works, b&c alternator aircraft, prestolite aircraft alternator, aircraft alternator repair, lightweight aircraft alternator

0 Comments